Abstract

Bone Scaffold is a three-dimensional porous construction which provides support to promote natural cell growth in damaged or broken section of bone. In recent years researchers from various departments like biomedical, mechanical, orthopedics, have shown significant interest in adopting ‘Bone Scaffolds’ as a promising treatment for bone defects. ‘Bone Scaffold’ is a honeycomb-like architecture composes of bio-compatible material having grater advantages over current grafting solution. In this paper, the authors try to review the available e-articles in an organized way on the bone scaffold in the field of biomedical implants with 3D printing. The selected literature mainly focuses on the biocompatible material and various advanced manufacturing methods used for manufacturing / preparing of bone scaffolds. This article tries to padding the gap between theoretical and actual implementation of ‘Bone Scaffolds’ by properly analyzing selected research and allowing future opportunities for reinventing the new possibilities in the field of biomedical.

Author Contributions

Academic Editor: V. Dhinakaran, CHENNAI INSTITUTE OF TECHNOLOGY, India.

Checked for plagiarism: Yes

Review by: Single-blind

Copyright © 2019 Nimisha Shirbhate, et al.

This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Competing interests

The authors have declared that no competing interests exist.

Citation:

Introduction

The internal backing network of the body is nothing but a architecture made up of a bones and which makes them so crucial. Bones are nothing but the honeycomb like structure of tissues. Human life in its entire lifespan may come across various incidents such as accidents, injury or some kind of diseases which may lead to bone damage. During the course of lifetime bones also undergo a process of degeneration. To facilitate the natural reworking / regeneration of bones, it is necessary to repair the damaged tissues or facilitate the growth of tissues naturally. The bone fractures are of two types first, in which it get self-repair after fracture because of small in size. While in second type larger fractures fall, they can’t heal perfectly by themselves and that is called as segmental bone defect.

‘Bone scaffolding’ is ressuring treatment in the field of medical orthopedic method over ‘Grafting’. Grafting is nothing but accumalation of bone tissue from one location to another in the same patient which is called as (an auto-graft) or from one person to another, this transplantation is called as (allo-graft). This ‘Bone grafting’ practice is not only pricey but also hurtful. Moreover, there is always a chance of elemination of tissues by the human immune sensetive system. Bone scaffold can play a serious role in beaten such problems.

This issues related with grafting can be removed or overcome with pours bone scaffolds, which will facilitate the regrowth of the tissues in the scaffold naturally. These bone structure can be made with various biocompatible materials and afterwords be implanted at the site of cripple in the human body. To make bone scaffolds, with honeycomb like structure, is a herculean task if pursued through conventional manufacturing techniques and the certainty of success remains doubtful. Additive manufacturing technologies have unbolt new possibilities like 3DP which could contribute in the ability to print bone substitute material.

The bone scaffold can be implanted in human body as well as in animals, wherever the cells are damaged due to some disease or broken bone. In the field of biomedical, speciffically in bone scaffolding one can recognise exceptional growth. In this area,research by academician are also active in the field of biomedical applications and it is expected to grow consistently in the future. In past some years, researchers and doctors from biomedical and mechanical engineering are showing compelling interest in bone scaffolds.the research objective of this study are

RO1. To analyse bone scaffolds for Mechanical properties such as, Tensile Strength, compressive strength, Fracture toughness etc. in static condition with variable porosity and material

RO2. To analyse scaffolds for Mechanical properties such as, Tensile Strength, compressive strength, Fracture toughness etc. in dynamic condition.

RO3. To validate simulation results with experimental.

Bone Scaffold

The word Bone scaffold is defined as three-dimensional (3D) biocompatible material that offers an advisable environment for cells to buildup tissue growth. The intention of current research article is to analyses specifically bone scaffolds. Those are able to contribute to regenerate signals from brain to the cells and allow bringing back natural growth of cells. Investigators and researchers trying to establish various new ways of producing bone scaffolds with different biomaterials. That bone scaffolds are nearly same to provide the natural essential environment, with mechanical properties. The required 3D scaffold should comprise of an ideal properties like biocompatible in order to avoid infections and all, biodegradable to get dissolve in body and with similar kind of mechanical properties of bone so that can be easily sustain in human body. (Figure 1)

3DPrinting

Acceptance of additive manufacturing technique in the area of bone scaffolding has been expanding in modern years. A distinct variety of production techniques and the biocompatible material along with the promising 3D printing have been used to buildup inventive options to currently using bone grafts. 5 The leading benefits of 3DPrinting is that it can built up Complicated three dimensional shapes with extremely high quality, required porosity and disciplined internal architecture. A distinct biocompatible and biodegradable material such as various materials, polymers and some kind of ceramics as well, has been extensively used in dynamic 3D printing.

Conventional Scaffold Fabrication

Previously, when there was unavailability of additive manufacturing techniques, still Bone scaffolds got manufactured using different traditional or conventional methods such as solvent casting, salt leaching Chemical or gas foaming, phase separation, freeze drying, thermally comprised and foam-gel are some of the methods used in previous research. Yet, using these conventional methods it was difficult to control porosity, defined shape, its internal architecture and connectivity in-between. 5, 6.

Systematic Literature Review

A comprehensive review on Bone scaffold, as an alternate treatment to damaged or fractured bone. In this section of the research article, various important factors for bone scaffold are taken into considerations which again are found out from the articles published in the area of bone scaffold. And the brief literature review of bone scaffold has been carried out to understand about material and manufacturing processes used for formulation of bone scaffold by different good articles. Study of bone scaffold has been carried out to facilitate the treatment of bone which is one or the other way got damaged. To carried out this important review, research articles from year 2005 to 2020 are studied and listed below:

Barbara Leukers et al 2005

Scrutinized the advantages of 3D printing approach and explore the actual performance of cells cultivated on the scaffolds in controlled atmosphere. They prepared bone scaffold by 3D printing technology and HA as biomaterial tested in vitro and found that this scaffold is very suitable for bone replacement 1

Marcin Lipowiecki, Dermot Brabazon2010

Examined and work towards the aim to design a highly osteoconductive and mechanically capable bone scaffold for regeneration of tissues which can be successfully manufactured . They designed three type of bone scaffold structure cubic hexagonal and triangular in which they used different porosity. Solid edge 3D modeling software used for design and ANSYS software used for analysis. In which they checked for stress strain behavior. They conclude that geometrical structure also plays important role in stress distribution as well as in cell regeneration. 2

Susmita Bose et al 2012

Reexamined latest advances in the same field of bone scaffold and the bone tissue engineering scaffold and found that, biocompatible materials were firstly opted for structural rehabilitation based on their biological and mechanical properties. Afterwards bone scaffolds were made to be bio-active or bio resorbs able to improve growth of the tissues. After reviewing the many of the research articles they enlisted requirements of idle bone scaffold like, Biocompatibility, Mechanical properties, pore size and survivability. 3

Susmita Bose et al 2013

Reviewed history and methodology of 3D printing and mentioned various rapid prototyping methods with process details, process material and advantages. Also they identified that after every preprocessing, post processing treatment is very important, for the parts processed by 3D Printing. Sintering, coating with other material or densification by means of heating at high temperature are example of this kind of post-processing but at the same time there may some modification occur in the shape and size due to post-processing 4

Pei Feng et al 2014

Examined and identified the performance offormulated well-internally connected penetrable (b-TCP) scaffolds as a means of manufacturing technique using Laser Sintered process (SLS) and found that, the bio-mechanical properties of the scaffolds can be even better by injection of zinc oxide into it (ZnO). After experimentation they experienced that the mechanical properties like toughness and strength can be improve. 5

Shailly H. Jariwala2015

Describes the inclination against additive manufacturing technology link with the CADand analyze the advantages and disadvantages of material used for each of the method of additive manufacturing technology. He also identified 3D Printed HA scaffolds were shown improved mechanical properties. 6

Oscar Robles-Vazquez et al 2015

Reviewed the extant literature on testing capabilities for the classification of mechanical properties of different section such as films, membranes, hydrogels and fibers which are frequently used as scaffolds in bone scaffold tissue engineering. They also investigated the mechanical behavior of developed scaffold loaded with polymeric biomaterial using theory of rubber elasticity. 7

Jia An et al 2015

Reviewed various research articles and explored the highest development in the study of different addictively manufacturing technologies such as Direct 3DP, SLS Selective Laser Sintering, FDM Fuse deposition method. And the scaffold architecture design for process parameter and limitation. 8

Sorumlu Yazar 2015

Focused their research towards powder based 3D printing specifically. They designed bone scaffold using CAD software and printed with the help of powder bed technology after conducting experimental tests He claimed that the biocompatible material such as, hydroxyapatite β-tricalcium phosphate and calcium sulphate are really good in cell regrowth. Powder based three dimensional (3D) printing have prominent over others technique because of the various advantages such as design and very importantly excellent control of inner and outer structure. 9

F.S.Senatovn et al2016

Identified and analyses the mechanical properties and behavior of poly lactide (PLA)/15wt% hydroxyapatite(HA) of 3D printed bone scaffold. They printed bone scaffold by using fused deposition method. For mechanical testing universal testing machine were used for the sample dimensions of 24mm X 12.5mm for compression tests. Phase transition were also studied at various temperature 10

Ahmed Munaz et al 2016

Discussed in thoroughly recent advancement in creating bio-inks and hurdels in bone tissue built up with scaffold or without scaffold. They used materials as calcium phosphate,tri-calcium phosphate, (PLA), poly-glycolic acid (PGA), poly-caprolactone (PCL) have been used to create bio-ink for hard materials and also discussed applications of 3D bio-printing. 11

R. Fradique et al 2016

Evaluated theavailable treatment for bone injuries and approaches towards scaffolding by Rapid prototype technologies as promising method. They usedtricalcium phosphate (TCP)/alginate RP scaffold and studied for compression test and young’s modules from stress-strain relationship curve. Swelling capacity of scaffold was also determined. 12

J. Jancar, a et al 2017

Explored the effect of modification of the cross-linked collagen with hyaluronic acid, hydroxyapatite nanoparticles and chitosan Nano-fibers materials on the mechanical response of the bone scaffold material and the partially porous bone scaffold inspected in the dry state at temperature near about 37 ˚C which is considered as normal body temperature under mechanical loading and found that, reduces the tensile elastic module and increase the ultimate deformation with the addition of hyaluronic acid. 13

Liang Dong et al 2017

scrutinized the effectiveness of chitosan hydrogel filled 3D Printed PCL scaffold. The manufacturing method for bone scaffold used was fused deposition method. Further they carried out VITRO and VIVO study. They found that the hydrogel extremely hydrated which is the source for cells adherence, procreation and differentiation, and which again allows easy transmission of nutrients and metabolic waste with interlinked tissues. 14

Tong Wu et al 2017

analyzed utmost recent research papers on bone scaffold within the era of design, material and the performance of bone scaffold. He discussed that materials and their performance are important problem while developing the bone scaffold. By review they state that, theoretically, titanium and hydroexpytite mixture is idle combination. 15

Aleš Gregor et al 2017

Designed, manufactured and tested scaffold structure for Mechanical properties and cell prolifetion. For the test the model designed and manufactured for the 90% porosity.and for printing this scaffold fused deposition method was used and biocompatible material polylactic-acid were used. 16

Saman Naghieh 2018

Fabricated bone scaffold by 3D bio printing as method of manufacturing and alginate solution as material and studied for mechanical properties. Mechanical experimentation in controlled environment was carried out in order to evaluate the mechanical properties like elastic behavior of the bone scaffolds from the observed stress-strain curves 17

Xiaotong Wang et al 2018

Manufactured and examined 3D-printed HBC hydrogel scaffold. The scaffolds were designed for the dimensions as a 24 mm × 24 mm × 5 mm cubic with a framework structure. The experimentation conducted for compressive strength and behavior of scaffold within elastic limits using mechanical testing equipment’s. Elastic modules were calculated from stress strain curve. 18

Gareth Turnbull et al 2018

Emphasized on scaffold as better treatment over grafting, as grafting may leads to infection, cancer or arthritis. A various type of bio-compatible materials and the distinct manufacturing processes including modern 3D printing used to build up novel options to cure bone defect as co related over traditional treatment of bone grafts. The individual material from each of the batch of different kind such as polymers, ceramics and hydrogels individually unable to recreate the bone properties entirely. Whereas encouraging mechanical properties of material can be combined as materials are used together in the composite form for 3D scaffolds. 19

Jingyu Liu and Cheng Yan 2018

Reviewed various 3Dprinting technologies for bone scaffold manufacturing such as Powder based 3D printing, Ink based 3D printing, Polymsization based 3D printing. At the same time thrown light on 4D printing as well in which they mentioned fourth dimension as time. They also mentioned that flexible manufacturing is one of the important advantages of 3D printing. They also stated that, morphology, structure and pore size still are challenges in 3D Printing. 23

Xiaoyu Du,a Shengyang Fua and Yufang Zhu2018

Reviewed recent literature on bone scaffold and state that, favorable osteogenic ability and mechanical properties are promising candidates for bone repair. They reviewed ceramic based scaffold with additive manufacturing. They also summarized materials and properties used for 3D printing of ceramic scaffold such as for Bioinert ceramic scaffold and for bioactive ceramic scaffold. They have explained case study as well in which the bone scaffold was implanted in rabbit for skull defect and the cell growth after every four weeks examined till 12 weeks and found satisfactory. 20

Ji, K., Wang, Y et al2018

Published short paper in which they mention that, The reuired bone scaffold should able to heal the bone defect completely and at the same time restore the bone tissue function at its highest performance , The human body inside is very complicated, so keeping this complication in account the bone scaffold should have some properties as microstructure features, mechanical strength, and most important is biocompatible. They also explain different 3D printing technology at the same time stated some challenges in this technology. 21

Bruyas, A et al 2018

Carried out their research on bone scaffold and thy printed the designed model with fused deposition method thy used biocompatible material as b-tricalcium phosphate and polycaprolactone. For porocity they used relation as P= 1-(Vc/Vt). they examined chemical composition and found that contact angle and surface roughness are related to the degradation rate.They had mechanical experimentation and analysis too. Also examined the effect of porosity on mechanical properties. 22

Petra Chocholata et al 2019

Reviewed about advanced and rapidly expanding field of biomedical also declared some disadvantages of auto graft and allograft. Explained how bone is important structure in human body and if they are treated with bone scaffold, what are the various important properties of material used for bone scaffolds. 24

Yidi Zhang et al 2019

Fabricated and examine material as poly (lactic-co-glycolic acid) (PLGA)/β-tricalcium phosphate (β-TCP) composite scaffold by different additively manufacturing method. Also performed vivo experiment on 24 male Wistar rats in ANOVA and figured out the result of vivo test after 4 weeks and after 12 weeks. They also picked up bone surface of the lately formed bone from scaffold in the critic-size defects. 25

Huawei Qu et al 2019

Reviewed article publish in English from January 1, 2010 to January 1, 2019. They also compose the bone in hierarchy as well they bordered some characteristics with advantages and disadvantages of various available biomaterials incorporate in fabrication of bone tissue engineering scaffolds. In this way they summarized literature about biomaterials used to construct bone scaffold. 26

Febe Carolina Vazquez-Vazquez2019

Emphasized their research specifically on bone scaffold. They manufactured cylindrical tubular scaffold with the help of 3Dprinting technique. PLA used as a fabricationmaterial. They had again used technique named air jet spinning and both techniques used for creation of bone scaffold. They analyses these scaffold for same microstructure and similar geometry. They conclude that using AJS technique evenly coated the layer of fiber membrane. Scaffolds which were coated with fibers allow hFOB cells to adhere and proliferate better than uncoated 3D tubular scaffolds showing that the fibers work as a platform to improve cell biocompatibility. 27

Jingqi Ma et al 2019

Fabricated bone scaffold of porosity about 74-76% with the help of very well-known 3D printing technology. They used material for fabrication in groups such as PCL, PCL/PVAc, PCL/HA and PCL/PVAc/ HA they tested these all four groups in controlled environment on animal for morphological biological and for mechanical properties as well and had comparison. After experimentation they concluded as the bone formation they received in two ways one is the new bone formed directly on the grid matrix, and the other is the new bone initially formed in the center of the scaffold channel and then remolded to concentric circles. 28

They tested these all four groups in controlled environment on animal for morphological biological and for mechanical properties as well and had comparison.

Chong Wanga et al 2020

Carried out research and found that, Three dimensional printing of bio-ceramic pastes pursue by sintering can improve bone formation. Cryogenic 3D printing of polymer solution with drug injected in it for backing cell differentiation simultaneously post processing of 3D printed scaffolds advances the cellular responses. 29

Yingchun Zhao et al 2020

Summarized the information about the 3D printing technique and specifically about powder based technology. They also state that this technology hold good promise in the field of biomedical. They suggested biocompatible materials such as calcium phosphates, especially β-tricalcium 89 phosphate (β-TCP) which are nearly closer to the composition for natural bone. 30

Review Methodology

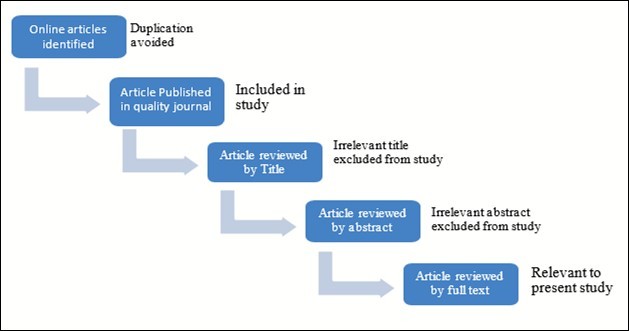

In the present literature, analysis is carried in a organized way to review the opted literature articles on the scaffold application in medical procedure. Firstly, the articles found out using the combination of key words terms ‘Bone scaffold’ AND ‘Biocompatible materials’ AND ‘3D Printing’ AND ‘Mechanical Properties’. The online searches were carried out to collect the research articles. Only good quality journal such as peer-reviewed journals are included in this study. Also, only English language articles were included.

Further, by studying the title and the content of the opted article, some articles were excluded from study as they were irrelevant. Figure 2 shows the article selection procedure. Total 30 articles were shortlisted for this study.

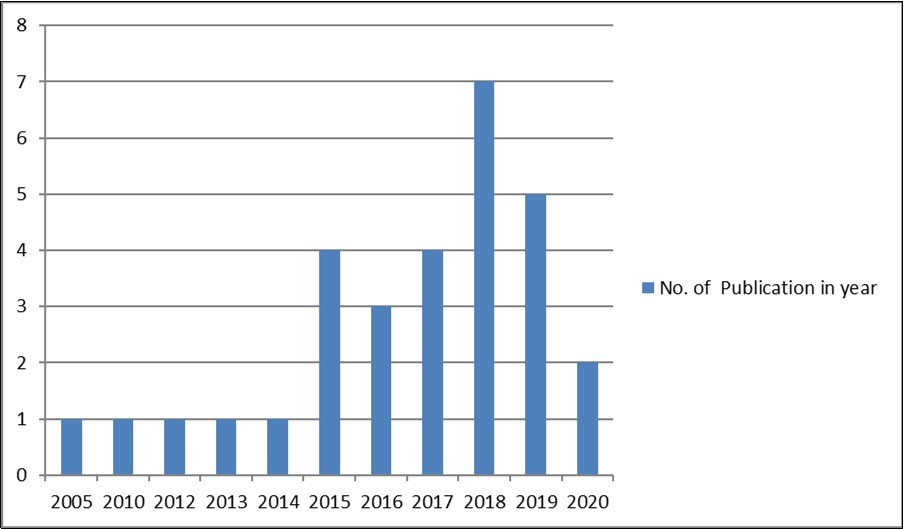

Distribution of Selected Articles with Respective year of publication

The allotment of used research papers in various journals broadcasted in the years 2005 to 2020 on bone scaffolds and biocompatible material using 3D Printing as manufacturing method. Figure 3 demonstrates the distribution of selected articles with respect to year of publication. As we can see from the graph there are fluctuations in the number of publications in the year 2005 to year 2014. There is sudden improvement in the number of publications per year in the year 2015 shows that a greater number of researchers are inclined in their interest towards bone scaffolding as option to treat bone defect. In the year 2018 it is at its peak.

Material and Manufacturing Techniques

Material is the most important aspect of this analysis. Mechanical properties predict its behavior in various operating conditions. Various researchers used specifically biocompatible materials and manufacturing technics too. In above acknowledged research articles they brought up with materials, their properties, their advantages and disadvantages. Below fig. shows materials and corresponding manufacturing technique for bone scaffold manufacturing. (Table 1)

Table 1. Material and Manufacturing techniques| Manufacturing Method | 3D Printing | SLS | SLA | FDM |

| Materials | PCLHydroxyapatiteBioactive glasses PCLHA / TCPHA / collagen | PCLNano HACalcium phosphatePlastic powderMetal powder | Β (TCP)Propylene FormulateHAPolymers Ceramics | ThermoplasticABSPLA (poly - lactic acid)Tricalcium PhosphateTCP/PolypropyleneTCP/PCL |

| Ceramics (calcium phosphates)PolymersComposites | Ceramic Powder | TCP/PolypropyleneTCP/PCL |

Discussion

From above literature review, we found that there are various researchers working in the field of biomedical especially in the area of bone scaffold to demonstrate scaffold is more talented treatment over allograft or auto graft. The research articles included in this study, manufactured bone scaffold or reviewed bone scaffold using various bio compatible material and 3D printing / RP as manufacturing techniques. In order to evaluate and figure out the properties and behavior of material used for scaffold, some of the researchers carried out experimentations such as compression test or tensile test. Few researchers implanted the 3D printed scaffold into animals like rat or rabbit, to know about the cell growth. Still the research was limited to static analysis of the 3D printed bone scaffolds. After implantation Bone scaffold it would be an integral part of human body. In order to make bone scaffold as successful treatment to bone defect, it is required to be tested for dynamic conditions as well. How the material will behave in dynamic condition needs to be figured out. Before going for the dynamic analysis researcher should know about the work which has been done in this area. This research paper presents systematic literature review of almost 30 papers in the same area which gives an idea about the number of manufacturing methods used by various researchers, the biocompatible material and the mechanical testing carried out by them. This review clearly shows till the time study were limited to static analysis, so for further study to be carried out in this area this paper will be expedient.

Conclusion

In this review paper the author tries to reevaluate the available literature on Bone Scaffold. We in this article presented a literature review for around 30 research papers for the publication period in between 2005 and 2020. Articles for reviewed were selected in a systematic way. The aim of this study was to know about various 3D printing methods used for manufacturing scaffold, biomedical materials used, at the same time the properties of idle scaffold and brief review of the Bone Scaffold.

This research work analyses different work in the area of bone scaffold Material, method and the behavior under different static loading conditions. For further research CAD model of the intended scaffold can be made using CAD software. The dimensions and shape of the scaffold may not be particular because, the damaged section of bone always changes with the patient. Keeping research objective focused the dimensions and size can be appropriately chosen. Porosity is important factor for the bone so, for different porosity different models can be made. These models will be helpful while manufacturing scaffold by 3D printing just by converting CAD file into .STL format. This bone scaffold can be then tested for various moving conditions (Dynamic analysis). This will provide information how it will behave in dynamic conditions.

Every research is intended toward modification, improvement and betterment and so is this. This study focuses on improvement in area of bone scaffold by static as well as dynamic analysis of bone scaffolds that a better material can be suggested with probably all properties which an ideal scaffold should possess.

References

- 1.Leukers Barbara, Lkan Hu¨ Lya Gu¨, Stephan H Irsen, Milz Stefan, Tille Carsten et al. (2005) Hydroxyapatite scaffolds for bone tissue engineering made by 3D printing”. , Journal of Materials Science: Materials In Medicine 16, 1121-1124.

- 2.Lipowiecki Marcin, Brabazon Dermot. (2010) . Design of Bone Scaffolds Structures for Rapid Prototyping with Increased Strength and Osteoconductivity” Advanced Materials Research .

- 3.Bose S, Roy M, Bandyopadhyay A. (2012) Recent advances in bone tissue engineering scaffolds. , Trends in Biotechnology 30(10).

- 4.Susmita B, Sahar V, Amit B. (2013) Bone tissue engineering using 3D printing”. , Materials 16(12).

- 5.Feng Pei, Wei Pingpin, Shuai Cijun, Peng Shuping.. Characterization of Mechanical and Biological Properties of 3-D Scaffolds Reinforced with Zinc Oxide for Bone Tissue Engineering. PLoS ONE 9(1): 1-13.

- 6.Shailly H J, Gregory S L, Zachary J B, James H A, Henry J D. (2015) . , 3D Printing of Personalized Artificial Bone Scaffolds”, Mary Ann Liebert, Inc 2(2).

- 7.Robles-Vazquez Oscar, Orozco-Avila Ignacio, Juan C Sánchez-Díaz, Hernandez Elena. (2015) An Overview of Mechanical Tests for Polymeric Biomaterial Scaffolds Used. in Tissue Engineering”,Journal of Research Updates in Polymer Science 4, 168-178.

- 8.An Jia.Joanne Ee Mei Teoh, Ratima Suntornnond. Chee Kai Chua.(2015). Design and 3D Printing of Scaffolds and Tissues” Engineering 1(2), 261-268.

- 9.Aldemìr B, Dıkıcı S, Karaman O, Oflaz H. (2015) Development, 3D printing and characterization of calcium sulfate based scaffolds for bone tissue engineering,". 19th National Biomedical Engineering Meeting (BIYOMUT), Istanbul 1-4.

- 10.Zadorozhnyy A V Maksimkin, Kaloshkin Y Z Estrin S D. (2016) Mechanical properties and shape memory effect of 3D-printedPLA-basedporousscaffolds”, jurnal of the mechanical behavior of biomedical materials. 57, 139-148.

- 11.Ahmed M, Raja K V, James S J, Matthew B, Harshad K et al. (2016) Three-dimensional printing of biological matters”. , Journal of Science: Advanced Materials and Devices

- 12.Fradique R, CorreiaS T R, Miguel1K P, D de Sa, Figueira D R et al. (2016) Production of new 3D scaffolds for bone tissue regeneration by rapid prototyping”. , Biomaterials Synthesis And Characterization 27, 69.

- 13.Jančář J, Slovíková a, Amler e, Krupa p, Kecová h et al. (2007) . Mechanical Response of Porous Scaffolds for Cartilage Engineering”Journal ofphysiological research .

- 14.Dong Liang, Wang Shao-Jie, Zhao Xin-Rong, Zhu Yu-Fang, Yu Jia-Kuo. (2017) 3D- Printed Poly (ε-caprolactone)Scaffold Integrated with Cell-laden Chitosan Hydrogels for Bone Tissue Engineering” scientific reports.

- 15.Wu T, Suihuai Y, Dengkai C, Yanen W. (2017) Bionic Design Materials and performance of Bone tissue. , Scaffold”, Materials Journal 10, 1187.

- 16.Gregor A, Eva F, Martin N, Jakub K, Hynek C et al. (2017) Designing of PLA scaffolds for bone tissue replacement fabricated by ordinary commercial 3D printer”. , Journal of Biological Engineering

- 17.Naghieha Saman, Mohammad Reza Karamooz-Ravarib, Eva Karkic Sarkera, Chen Xiongbiao. (2018) Influence of crosslinking on the mechanical behavior of 3D printed alginate scaffolds:Experimental and numerical approaches”. , Journal of the Mechanical Behavior of Biomedical Materials

- 18.Wang Xiaotong, Wei Changzheng, Cao Bin, Jiang Lixia, Hou Yongtai et al. (2018) Fabrication of multiple-layered hydrogel scaffolds with elaborate structure and good mechanical properties via 3D-printing and ionic reinforcement”, Applied materials and interfaces.

- 19.Gareth T, Jon C, Frederic P, Philip R, Luanluan J et al. (2018) 3D bioactive composite scaffolds for bone tissue engineering”. , Bioactive Materials 3, 278-314.

- 20.Xiaoyu D, Shengyang F, Yufang Z. (2018) 3D printing of ceramic-based scaffolds for bone tissue engineering: an overview”. , Journal of Materials Chemistry B 16.

- 21.Ji K, Wang Y, Wei Q, Zhang K, Jiang A et al. (2018) Application of 3D printing technology in bone tissue engineering. , Bio-Design and Manufacturing 1(3), 203-210.

- 22.Bruyas A, Lou F, Stahl A, Gardner M, Maloney W et al. (2018) Systematic characterization of 3D-printed PCL/β-TCP scaffolds for biomedical devices and bone tissue engineering: Influence of composition and porosity. , Journal of Materials Research 33(14), 1948-1959.

- 24.Chocholata Petra, Kulda Vlastimil, Babuska Vaclav. (2019) . , Fabrication of Scaffolds for Bone-Tissue Regeneration, Materials 12.

- 25.Zhang Yidi, Wang Chong, Fu Li, Ye Shan, Wang Min et al. (2019) Fabrication and Application of Novel Porous Scaffold in Situ-Loaded Graphene Oxide and Osteogenic Peptide by Cryogenic 3D Printing for Repairing Critical-Sized Bone Defect”. , Molecules 24.

- 26.Qu Huawei, Fu Hongya, Hana Zhenyu, Sun Yang. (2019) Biomaterials for bone tissue engineering scaffolds:a review”. , RSC Advances 9, 26252-26262.

- 27.Carolina Febe.Vazquez-Vazquez, Osmar Alejandro Chanes-Cuevas, David Masuoka.(2019). Biocompatibility of Developing 3D-Printed Tubular Scaffold Coated with Nanofibers for Bone Applications”,Journal of nanomaterials,9thmay.

- 28.Ma Jingqi, Lin Lili, Zuo Yi, Zou Qin, Ren Xin et al. (2019) Modification of 3D printed PCL scaffolds by PVAc and HA to enhance cytocompatibility and osteogenesis”,Royal society of chemistry.